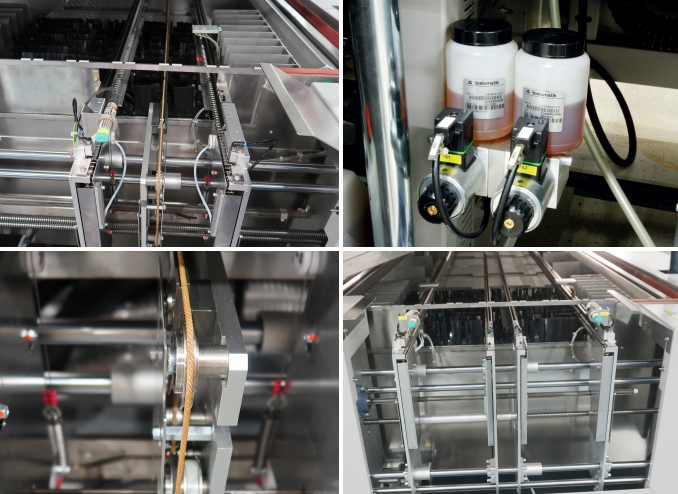

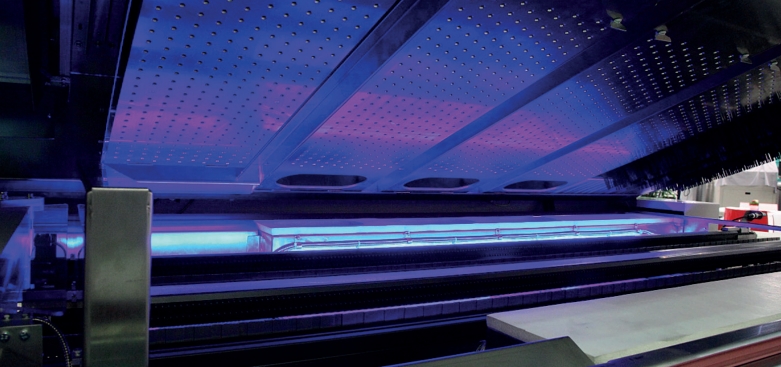

During the soldering process, electronic components pass through each zone of the system in sequence: from the preheating zone through the high-temperature zone to the cooling zone. For continuous processes, safe component transmission is particularly critical. Therefore, we provide you with a highly flexible conveyor system.

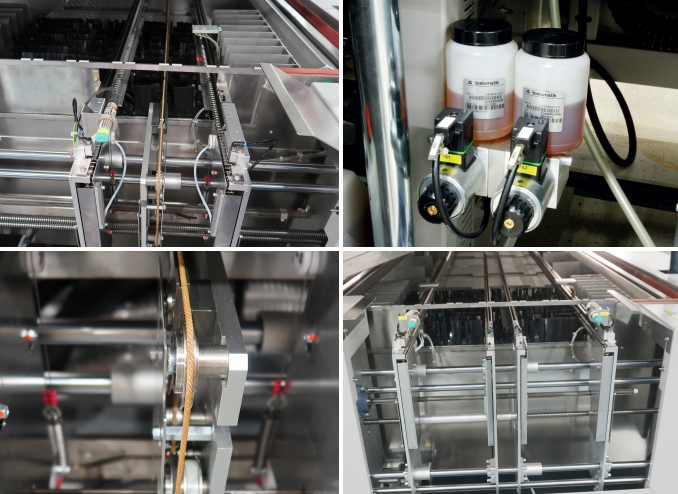

Our conveyor system can perfectly adapt to your components regardless of the circuit board geometry. In addition, both the conveyor track width and speed are flexibly adjustable, enabling parallel dual-track soldering within a single reflow soldering system. Depending on specific requirements, you can select different transmission modes, such as single-track and dual-track transmission.

When soldering large circuit boards or flexible substrates, the optional central support system prevents component deformation and ensures maximum process stability.

• Parallel transmission for reliable and trouble-free production

• Precisely adjustable conveyor width

• Temperature profile unaffected by the conveyor system or central support plate

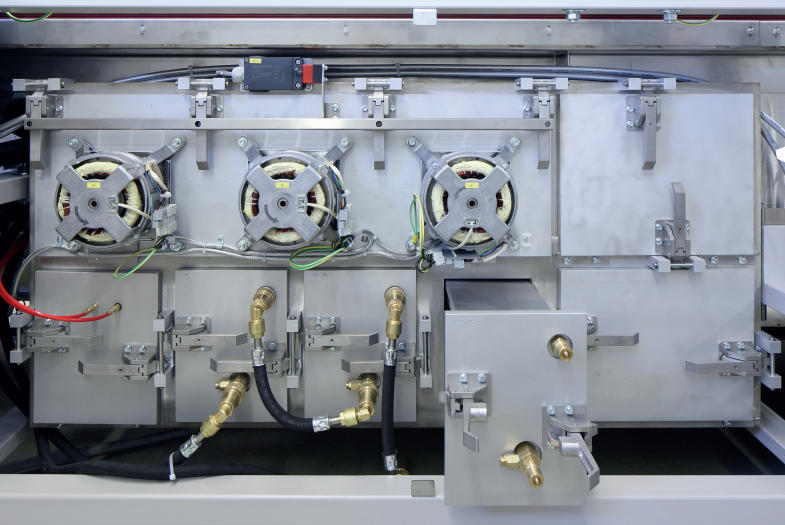

• Conveyor system drive mechanism located outside the furnace chamber, resulting in minimal maintenance requirements

• A variety of conveyor systems available to suit all applications

• Integrated central support plate for maximum process reliability

Top Left: Single-Track Transmission; Top Right: Track Lubricator

Bottom Left: Central Support; Bottom Right: Dual-Track Transmission

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd

,

,