Product Specification

Product Description:The Necessity of Using PCB Surface Cleaners

Dust and stains are likely to adhere to the PCB surface during handling, laser marking and storage processes.

Static electricity on the PCB surface will further attract dust particles.

As SMT components are becoming increasingly smaller, even tiny stains may affect the soldering quality.

At present, many customers use high-pressure air to clean PCB surfaces, which has such drawbacks as high noise, high energy consumption and secondary air pollution. It has become a fact that surface cleaning and static elimination before PCB placement will be an integral part of the production process, both now and in the future.

Product Features:

* Integrated sheet metal frame structure with heavy-duty design for enhanced stability

* Independent dual servo lifting system for faster and smoother operation

* Independent dual NG magazines and dual OK magazines for convenient use

* Easy width adjustment design for quick and flexible line changeover

* Independent dual HMI touch screens for user-friendly operation

* High-precision ball screws and linear guide rails for high-speed and low-noise performance

* 4-point positioning for magazines

* CE certified with top safety level design

* Special communication interface with AOI systems

Options:

A-Static Electricity Monitoring System B-MES (ASM, Panasonic, FUJ Systems) Integration C-Eyong System D-Others

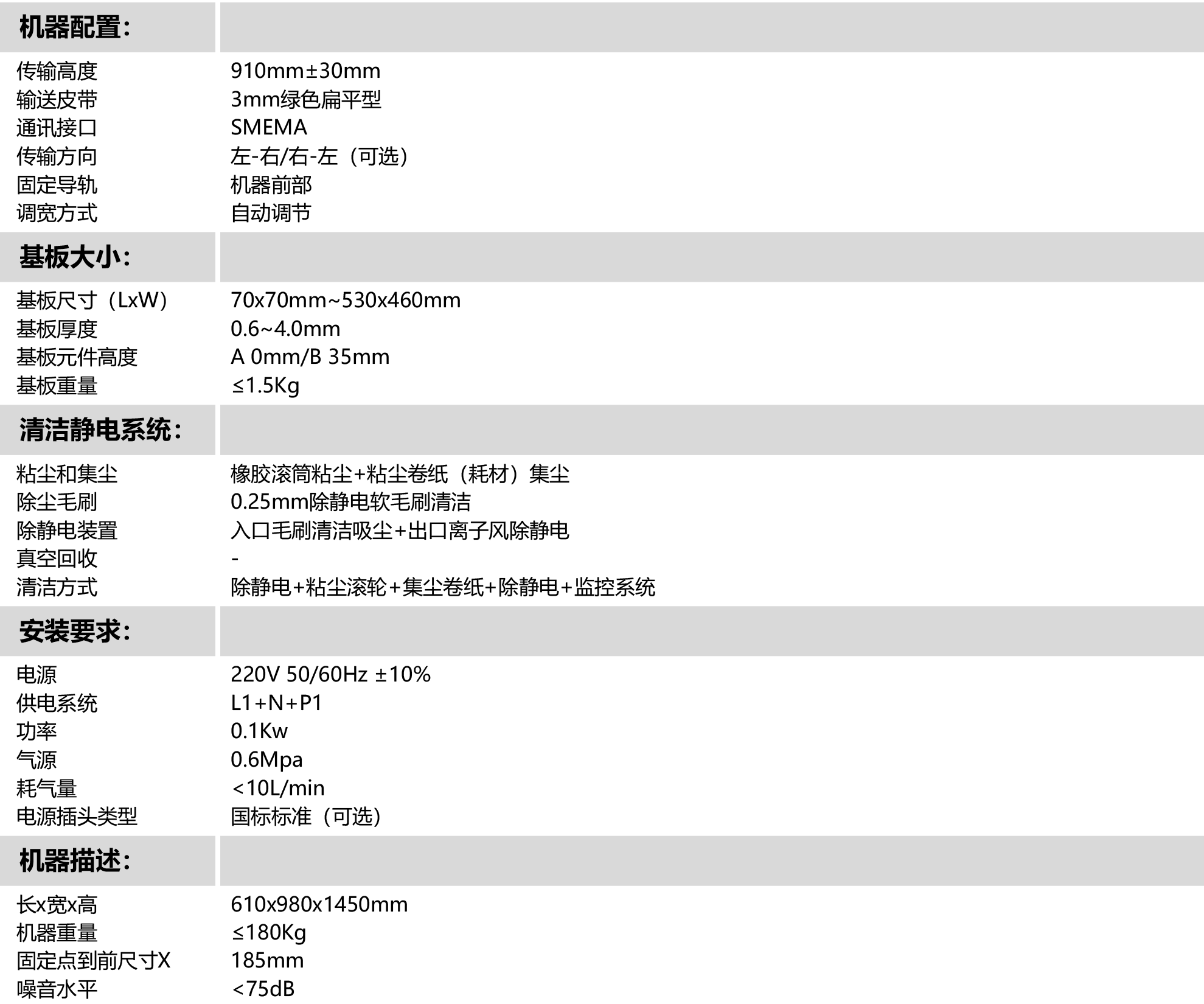

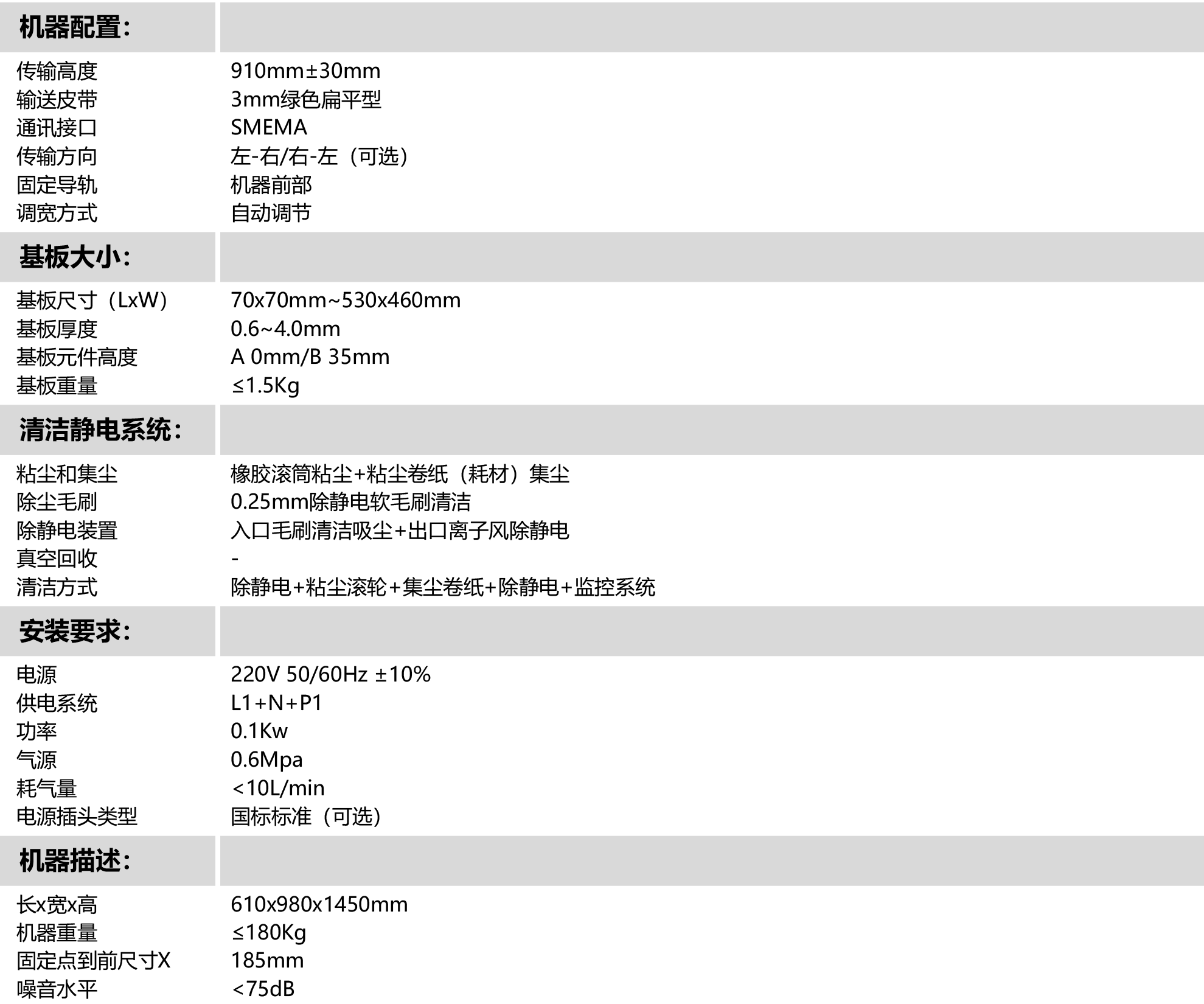

Technical Parameters:

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd