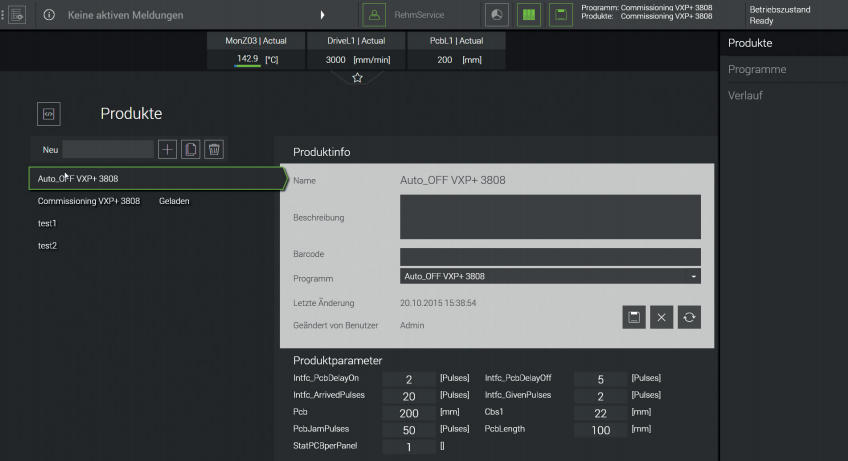

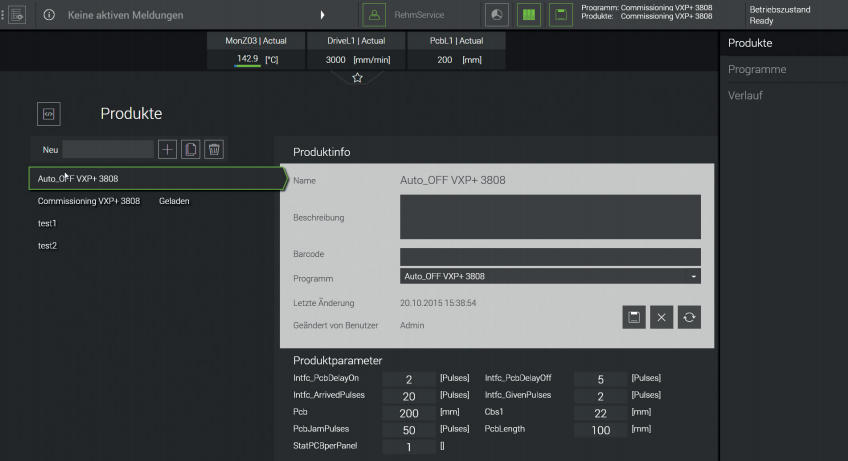

Rehm has developed the straightforward ViCON software for the VisionXC reflow soldering system, providing you with an intuitive operating experience via a touch screen.

Through the equipment view on the main interface, you can easily access all information, commands, and parameters. ViCON offers a range of outstanding features, such as a freely configurable favorites bar, structured parameter grouping, independent process tracking and archiving, etc., providing optimal support for your production process.

During the software development phase, Rehm experts made in-depth improvements in many areas, including product management—for example, supporting the creation of new products or copying specific attributes while production is in progress. Additionally, parameters can be directly set when creating new products, which means production can be launched more quickly without any interruptions.

Similarly, you can immediately identify the system's operating mode based on the working status, detect errors more quickly, and reliably evaluate alarm information.

Another major advantage of the ViCON software is its support for user management. By flexibly assigning user roles, each user can obtain corresponding operating permissions—no strict hierarchy is required.

• Intuitive software operation with touch screen

• Clear product management supporting offline programming

• Parameter transparency through module grouping

• Favorites bar for easy adaptation to different processes

• Multi-language support

Clear Product Management with Offline Programming Support

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd

深圳市柏宇电子科技有限公司

Shenzhen boyu Electronic Technology Co., Ltd